Painting, Mask Making, Paperclips

What’s been happening at i3 lately? A bunch of things. But, here are some highlights.

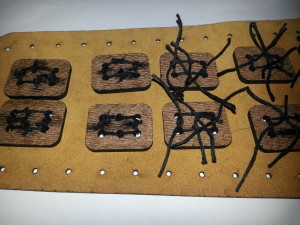

Karriane G. taught a few classes on leather mask making. It was perfect timing right before halloween. Students learned the basics of forming with leather, and were able to follow through creating their own design, adding hardware such as studs and grommets, and finally painting their creation. They’re all set for a masquerade!

Kevin F. has been busy teaching oil painting classes. These have been insanely popular, often filling up within a day. It’s so amazing to see people come in and learn new techniques. Most of the students came with little-to-none painting experience, but all left with smiles on their faces.

Matt O. has been working on his halloween costume. Can you guess what it’s going to be? Here’s a hint: “It looks like you’re trying to write a letter!”

Of course making a giant paperclip out of metal would be insanely heavy, so it’s actually that universal crafting material, the grown-up version of popsicle sticks: Schedule 40 PVC! Bent and formed by a combination of hot air, teamwork, carefully placed screws, and minor burns.