Drill Press Clamp Safety

| This page is a candidate for deletion. The given reason is: Move to tool page?

If you think this article should be saved please remove this message and make the necessary improvements to keep this article on the wiki. Remember to check if anything links here before deleting. Also if there are images used on this page that won't be useful elsewhere maybe delete that as well. Thank you! Last edit by: Mtfurlan (talk · contrib) · Last edited on Wed, 23 Jun 2021 20:39:10 +0000 |

The Rapidly-Rotating Scythe FAQ

by Mr. Dwis N. Wid [1]

Technical Review by Steve H. [2]

Q. How can you safely drill a hole in a rapidly-rotating scythe?

A. I'm glad you asked that. The true heart of the matter, in other words, the central main salient key crux of focus, as it were, is the rapid rotation. Minimize this.

Q. Um..., how often are rapidly-rotating scythes encountered at i3 Detroit?

A. It's not as unlikely as you might expect, even when there happen to be no circus performers around. When you drill a hole in a piece of sheet metal, there is always a chance that the metal will buckle around the bit and catch. If this happens, a small bit will either break or stop while the drill chuck slips around it. A large bit will do its best to whirl the sheet metal around at drill-motor speed. Its best can be pretty darned impressive. Even if you are experienced with hand-held drills, you may be astonished by how much workpiece-rotating torque is instantly available from an ordinary drill press.

Q. OK, but strictly speaking, that is a piece of sheet metal, not a scythe, right?

A. Anyone who has seen this happen up close and personal will tell you that you are making what is known as “a distinction without a difference”. Even more exciting, if the hole is not in the center, the workpiece can be hurled away from the drill if it works it way off before you push the stop button. (The stop button is located directly above the rapidly-rotating scythe, for your convenience [3].)

Q. You've convinced me. How can I make sure to keep the rapid rotation to an absolute minimum?

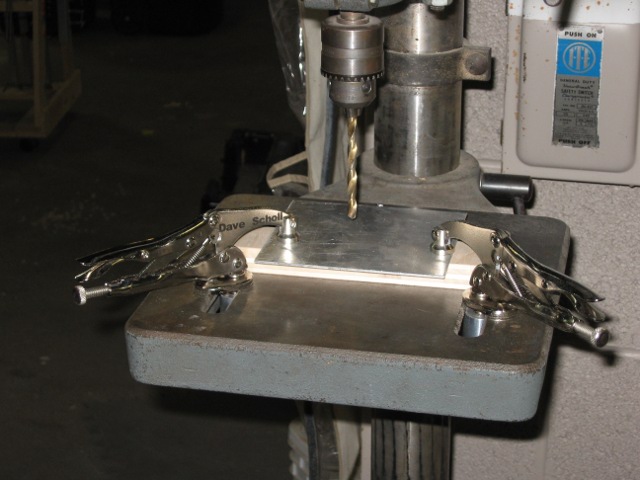

A. Clamp your workpiece to something strong enough to either (1) break the bit or (2) hold the bit still while the drill chuck slips around it. The larger the bit, and the smaller the workpiece, the more challenging this can be (Thanks, Archimedes!). Try clamping your workpiece to the drill press table. For larger workpieces, you can apply wood-clamps at the edge of the drill press table (see Figure 1). For smaller workpieces, try the metal clamps that resemble vise-grip pliers (see Figure 2). They attach to the slots in the drill press table, so they can clamp near the drill. If these won't work for you, ask other members for ideas, and consider making a special clamping fixture.

Q. Does any of this apply to drilling holes in bar stock, plates, or other thicker shapes?

A. Hold on while I change our title to “The Rapidly-Rotating Truncheon FAQ”. OK, I'm back. Yep, it sure does. With thicker stock, contusions are more of a concern than lacerations, but that's about the only difference. The trickiest time is when the drill bit is nearly ready to break through, as the remaining material is thin enough that it can catch like sheet metal. Unlike sheet metal, you may be able to clamp these thicker shapes safely in a drill press vise. If not, the clamping techniques described here are strongly recommended.

Q. Does clamping provide a better quality hole in three ways?

A. Lucky guess! Clamping your workpiece: (1) reduces the chance that the drill will get caught, (2) reduces the damage to your workpiece if that happens, and (3) gives you a more predictable hole location. Here's another tip: if you clamp a piece of scrap wood under your workpiece, as shown in the figures, the wood helps provide support for the metal as the drill breaks through, which further reduces the chance that the bit will get caught.

Q. Any final thoughts?

A. Another lucky guess! Here they are:

- Respect the torque that the drill press provides, and make sure that torque will always go to a safe place.

- Take the time to ask for help if you're not sure. A trip to the ER takes time too, and it might hurt more than asking for help.

- Consider making a customized fixture, even to drill a single hole, if you need it to keep your workpiece locked down.

- Always wear your safety glasses!

Footnotes:

[1] “Do what I say, not what I do!”

[2] “40 years a tinsmith!”

[3] “Them's the breaks, Platyspus!”

Figure 1. Wood clamps

Figure 2. Vise clamps